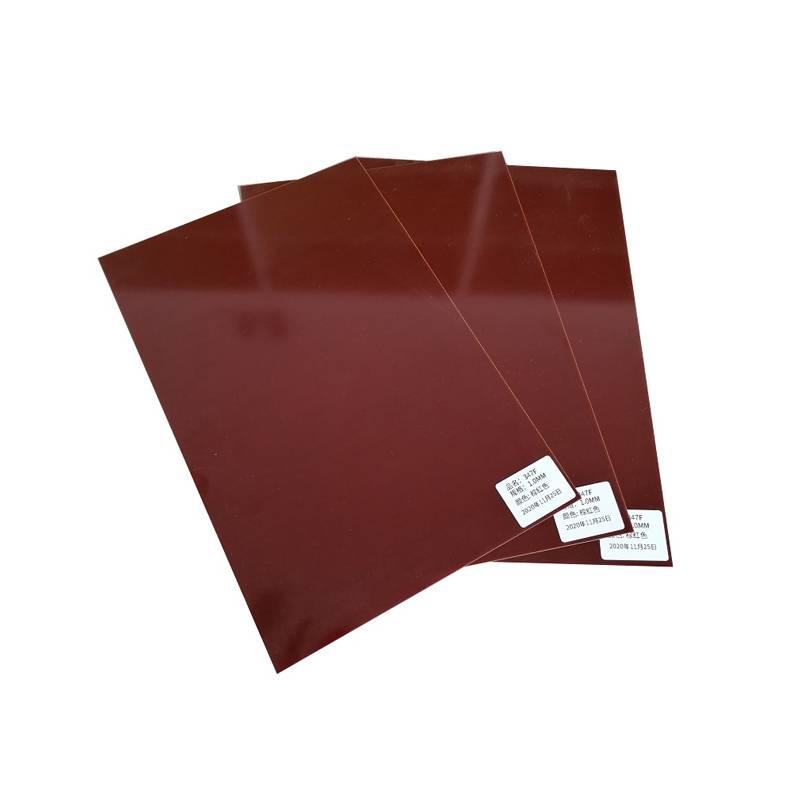

347/347F High Strength Epoxy Glassfiber laminated ntawv (Thermostability yog qib F)

Product Description

Cov khoom no yog ib daim ntawv laminated uas ua nrog cov txheej txheem uas tsis yog-alkali iav fiber ntau li cov ntaub ntawv thaub qab, los ntawm kub nias nrog qib F benzo oxazine resin. Nws muaj cov khoom siv hluav taws xob zoo thiab hluav taws xob zoo, thiab nplaim hluav taws kub, tshwj xeeb tshaj yog muaj zog txhua yam ruaj khov thiab cov khoom siv hluav taws xob zoo nyob rau hauv qhov kub thiab txias.Suitable rau qib F lub cev muaj zog thiab cov khoom siv hluav taws xob zoo li cov qauv rwb thaiv tsev zoo, muaj qhov zoo ntawm kev ua haujlwm zoo thiab siv dav hauv cov khoom zoo sib xws.

Nta

1.Txoj kev siv tshuab thiab hluav taws xob zoo;

2.High mechanical zog tuav thiab

cov khoom hluav taws xob zoo heev nyob rau hauv qhov kub thiab txias;

3.Moisture tsis kam;

4.Qhov kub tsis kam;

5.Tub kub tsis kam: Qib F;

6.Zoo machinability thiab dav applicability

7. Cov khoom siv hluav taws xob hluav taws xob: UL94 V-0

Ua Raws Li Cov Qauv

Raws li GB / T 1303.4-2009 hluav taws xob thermosetting resin muaj zog laminates - Ntu 4: epoxy resin hard laminates.

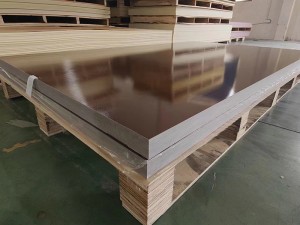

Cov tsos mob: qhov saum npoo yuav tsum tiaj tus, tsis muaj npuas, pits thiab wrinkles, tab sis lwm yam tsis xws luag uas tsis cuam tshuam rau kev siv yog tso cai, xws li: khawb, indentation, stains thiab ob peb qhov chaw.Lub ntug yuav tsum tau txiav kom huv si, thiab lub ntsej muag kawg yuav tsum tsis txhob delaminated thiab tawg.

Daim ntawv thov

Cov ntaub ntawv kev kawm ntawm 347F zoo ib yam li FR5, Tsim nyog rau qib F lub cev muaj zog thiab cov khoom siv hluav taws xob raws li cov qauv zoo rwb thaiv tsev.

Main Performance Index

| TSIS MUAJ. | Yam khoom | UNIT | INDEX VALUE | |||

| 347 ib | 347f ua | |||||

| 1 | Qhov ntom | g/cm³ | 1.8-2.0 Nws | 1.8-2.0 Nws | ||

| 2 | Tus nqi nqus dej | % | ≤0.5 | ≤0.5 | ||

| 3 | Vertical dabtsi yog khoov zog | Ib txwm | MPa | ≥440 | ≥400 | |

| 155 ± 2 ℃ | ≥280 | ≥250 | ||||

| 4 | Compression zog | Ntsug | MPa | ≥350 | ≥300 | |

| Parallel | ≥260 | ≥200 | ||||

| 5 | Impact zog (Charpy type) | Lengthway tsis muaj qhov sib txawv | KJ/m² | ≥147 | ≥129 | |

| Kab rov tav tsis muaj qhov sib txawv | ≥98 | ≥77 | ||||

| 6 | Bonding zog | N | ≥7200 | ≥6800 | ||

| 7 | Tensile zog | Ntev | MPa | ≥280 | ≥240 | |

| Kab rov tav | ≥200 | ≥180 | ||||

| 8 | Vertical zog zog (hauv roj ntawm 90 ℃ ± 2 ℃) | 1 hli | KV/mm | ≥14.2 | ≥14.2 | |

| 2 hli | ≥12.4 | ≥12.4 | ||||

| 3mm ib | ≥11.5 | ≥11.5 | ||||

| 9 | Parallel breakdown voltage (1 min hauv roj ntawm 90 ℃ ± 2 ℃) | KV | ≥45 | ≥45 | ||

| 10 | Dielectric dissiption yam (50Hz) | - | ≤ 0.04 | ≤ 0.04 | ||

| 11 | Volumn Insulation Resistance | Ib txwm | Ω | ≥1.0 × 1012 | ≥1.0 × 1012 | |

| Tom qab soaking rau 24 teev | ≥1.0 × 1010 | ≥1.0 × 1010 | ||||

| 12 | Combustibility (UL-94) | Qib | V-1 | V-0 | ||