Tuam Tshoj phenolic resin daim ntawv 3240

Product Description

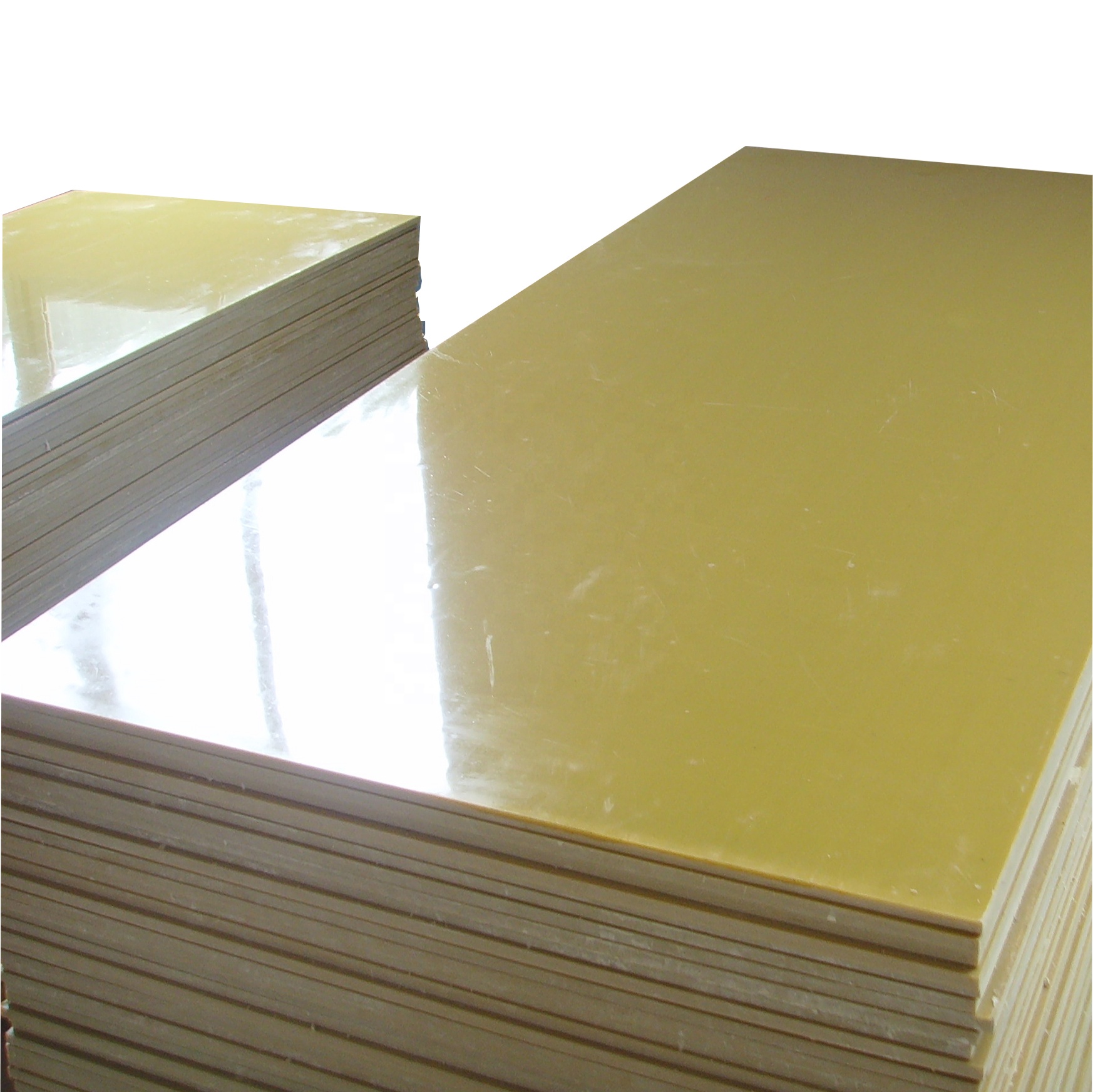

3240 Epoxy phenolic iav fiber ntau laminated ntawv (tsis muaj muab tub lim):Cov khoom no yog cov khoom laminated ua los ntawm hluav taws xob lub hom phiaj alkali-dawb iav daim ntaub impregnated nrog epoxy phenolic resin los ntawm kub nias.The thermostablity yog qib B.It muaj zoo txhua yam thiab dielectrical zog.,

Muaj feem xyuam rau txhua yam, hluav taws xob, hluav taws xob, hluav taws xob thiab lwm yam. Nws kuj tseem siv rau hauv kev ua cov khoom siv insulating, thiab ua tiav rau txhua yam ntawm cov khoom siv insulating thiab cov khoom siv insulating cov qauv, uas tuaj yeem siv rau hauv qhov chaw ntub dej thiab cov roj transformer.

3240 Epoxy phenolic iav fiber ntau laminated ntawv (Nrog muab tub lim):Cov khoom no yog cov khoom laminated ua los ntawm hluav taws xob lub hom phiaj alkali-dawb iav ntaub impregnated nrog epoxy phenolic resin thiab muab tub lim los ntawm kub nias .Vim tias 3240-B yog pheej yig dua 3240-A thiab muaj kev ua tau zoo, nws muaj ntau dua hauv kev ua lag luam. Yog xav paub ntxiv, thov ua siab zoo nrog peb tus neeg muag khoom.

Ua Raws Li Cov Qauv

TS EN ISO 60893-3-2-2011 Cov khoom siv hluav taws xob thermosetting resin muaj zog laminates - Ntu 4: epoxy resin hard laminates, IEC 60893-3-2-2011 insulating cov ntaub ntawv - hluav taws xob thermosetting resin industrial hard laminates - Ntu 3-2 ntawm cov khoom siv tshwj xeeb EPGC201.

Nta

1.Zoo mechanical zog;

2.Zoo dielectrical zog;

3.Moisture kuj, haum nyob rau hauv

ntub ib puag ncig thiab transformer roj.

4.Zoo machinability zog

5.Tub kub tsis kam: Qib B

Daim ntawv thov

1) Siv nyob rau hauv cov neeg kho tshuab kev ua tau zoo ntawm lub cev muaj zog, cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob insulating

2) ICT, ITE tswj kev ua ntawm cov rwb thaiv tsev qhov chaw, kuaj fixtures, silicon roj hmab keypads pwm

3) Fixture phaj, pwm plywood, countertops sib tsoo phaj, ntim tshuab, zuag, thiab lwm yam

Main Performance Index

| TSIS MUAJ. | Yam khoom | UNIT | INDEX VALUE | ||

| 1 | Qhov ntom | g/cm³ | 1.8-2.0 Nws | ||

| 2 | Tus nqi nqus dej | % | ≤0.5 | ||

| 3 | Vertical dabtsi yog khoov zog | MPa | ≥340 | ||

| 4 | Vertical compression zog | MPa | ≥350 | ||

| 5 | Parallel cuam tshuam lub zog (charpy type-gap) | KJ/m² | ≥33 | ||

| 6 | Parallel impact zog (cantilever beam method) | KJ/m² | ≥34 | ||

| 7 | Parallel shear zog | Mpa | ≥30 | ||

| 8 | Tensile zog | MPa | ≥200 | ||

| 9 | Vertical zog zog (hauv roj ntawm 90 ℃ ± 2 ℃) | 1 hli | KV/mm | ≥14.2 | |

| 2 hli | ≥11.8 | ||||

| 3mm ib | ≥10.2 | ||||

| 10 | Parallel tawg voltage (hauv roj ntawm 90 ℃ ± 2 ℃) | KV | ≥35 | ||

| 11 | Dielectric dissiption yam (50Hz) | - | ≤ 0.04 | ||

| 12 | Rwb thaiv tsev Resistance | Ib txwm | Ω | ≥5.0 × 1012 | |

| Tom qab soaking rau 24 teev | ≥5.0 × 1010 | ||||