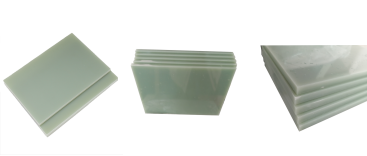

luv nqi Tuam Tshoj G11 Epoxy iav Laminated Insulated Sheets

Peb tseem tab tom tsom rau kev txhim kho cov khoom tswj hwm thiab QC system kom peb thiaj li muaj txiaj ntsig zoo hauv kev lag luam hnyav-kev sib tw rau luv nqi Tuam Tshoj G11 Epoxy iav Laminated Insulated Sheets, Peb caw koj thiab koj lub lag luam kom muaj kev vam meej nrog peb thiab koom nrog lub sijhawm ntev hauv ntiaj teb.

Peb tseem tab tom tsom mus rau kev txhim kho cov khoom tswj hwm thiab QC system kom peb tuaj yeem khaws cov txiaj ntsig zoo hauv kev lag luam hnyav-kev sib tw rauTuam Tshoj Hluav Taws Xob Insulating Khoom, Insulated Laminated iav, Tam sim no peb tau txais kev lees paub ntau ntawm cov neeg siv khoom thoob plaws ntiaj teb. Lawv tso siab rau peb thiab ib txwm muab cov lus txib rov qab. Tsis tas li ntawd, tau hais hauv qab no yog qee qhov tseem ceeb uas tau ua lub luag haujlwm tseem ceeb hauv peb txoj kev loj hlob zoo hauv lub tebchaws no.

Product Description

Cov khoom no yog tsim los ntawm cov kws kho hluav taws xob uas tsis yog-alkali iav fiber ntau daim ntaub ua cov ntaub ntawv thaub qab, nrog siab TG epoxy resin li binder los ntawm kub nias laminated nyob rau hauv 155 degree kub.Nws muaj zog txhua yam nyob rau hauv ib txwm kub, tseem muaj zog txhua yam lub zog, zoo hluav taws xob nyob rau hauv qhuav thiab ntub ib puag ncig, yuav siv tau nyob rau hauv damp puag ncig thiab transformer roj. FR5, tab sis tsis yog hluav taws kub retardant.

Ua Raws Li Cov Qauv

TS EN ISO 60893-3-2-2011 Cov khoom siv hluav taws xob thermosetting resin muaj zog laminates - Ntu 4: epoxy resin hard laminates, IEC 60893-3-2-2011 cov ntaub ntawv insulating - hluav taws xob thermosetting resin industrial hard laminates - Ntu 3-2 ntawm cov khoom siv tshwj xeeb EPGC203.

Nta

1.High hluav taws xob stability nyob rau hauv high humidity;

2.Cov khoom siv kho tshuab zoo heev;

3.High mechanical zog nyob rau hauv qhov kub thiab txias;

4.High Moisture tsis kam;

5.High kub tsis kam;

6.Tub kub tsis kam: Qib F

Daim ntawv thov

Muaj feem xyuam rau txhua yam ntawm lub cev muaj zog, hluav taws xob, hluav taws xob thiab lwm yam kev lag luam, dav siv hauv lub cev muaj zog, cov khoom siv hluav taws xob xws li cov khoom siv hluav taws xob, hluav taws xob hloov hluav taws xob, kev hloov hluav taws xob siab (xws li lub cev muaj zog stator rwb thaiv tsev cov ntaub ntawv ntawm ob qho tib si, rotor kawg phaj rotor flange piece, slot wedge, wiring phaj, thiab lwm yam).

Main Performance Index

| TSIS MUAJ. | Yam khoom | UNIT | INDEX VALUE | ||

| 1 | Qhov ntom | g/cm³ | 1.8-2.0 Nws | ||

| 2 | Tus nqi nqus dej | % | ≤0.5 | ||

| 3 | Vertical dabtsi yog khoov zog | Ib txwm | MPa | ≥380 | |

| 155 ± 2 ℃ | ≥190 | ||||

| 4 | Compression zog | Ntsug | MPa | ≥300 | |

| Parallel | ≥200 | ||||

| 5 | Impact zog (Charpy type) | Lengthway tsis muaj qhov sib txawv | KJ/m² | ≥147 | |

| 6 | Bonding zog | N | ≥6800 | ||

| 7 | Tensile zog | Ntev | MPa | ≥300 | |

| Kab rov tav | ≥240 | ||||

| 8 | Vertical zog zog (hauv roj ntawm 90 ℃ ± 2 ℃) | 1 hli | KV/mm | ≥14.2 | |

| 2 hli | ≥11.8 | ||||

| 3mm ib | ≥10.2 | ||||

| 9 | Parallel breakdown voltage (1 min hauv roj ntawm 90 ℃ ± 2 ℃) | KV | ≥40 | ||

| 10 | Dielectric dissiption yam (50Hz) | - | ≤ 0.04 | ||

| 11 | Rwb thaiv tsev Resistance | Ib txwm | Ω | ≥1.0 × 1012 | |

| Tom qab soaking rau 24 teev | ≥1.0 × 1010 | ||||

Peb tseem tab tom tsom rau kev txhim kho cov khoom tswj hwm thiab QC system kom peb thiaj li muaj txiaj ntsig zoo hauv kev lag luam hnyav-kev sib tw rau luv nqi Tuam Tshoj G11 Epoxy iav Laminated Insulated Sheets, Peb caw koj thiab koj lub lag luam kom muaj kev vam meej nrog peb thiab koom nrog lub sijhawm ntev hauv ntiaj teb.

Tus nqi luvTuam Tshoj Hluav Taws Xob Insulating Khoom, Insulated Laminated iav, Tam sim no peb tau txais kev lees paub ntau ntawm cov neeg siv khoom thoob plaws ntiaj teb. Lawv tso siab rau peb thiab ib txwm muab cov lus txib rov qab. Tsis tas li ntawd, tau hais hauv qab no yog qee qhov tseem ceeb uas tau ua lub luag haujlwm tseem ceeb hauv peb txoj kev loj hlob zoo hauv lub tebchaws no.