G10 Epoxy Fiberglass Laminated Sheet

| Specification Txheej txheem cej luam | |

| Lub npe | G10 Epoxy Fiberglass Laminate Sheet |

| Khoom siv hauv paus | Epoxy cob + 7628 Fiberglass |

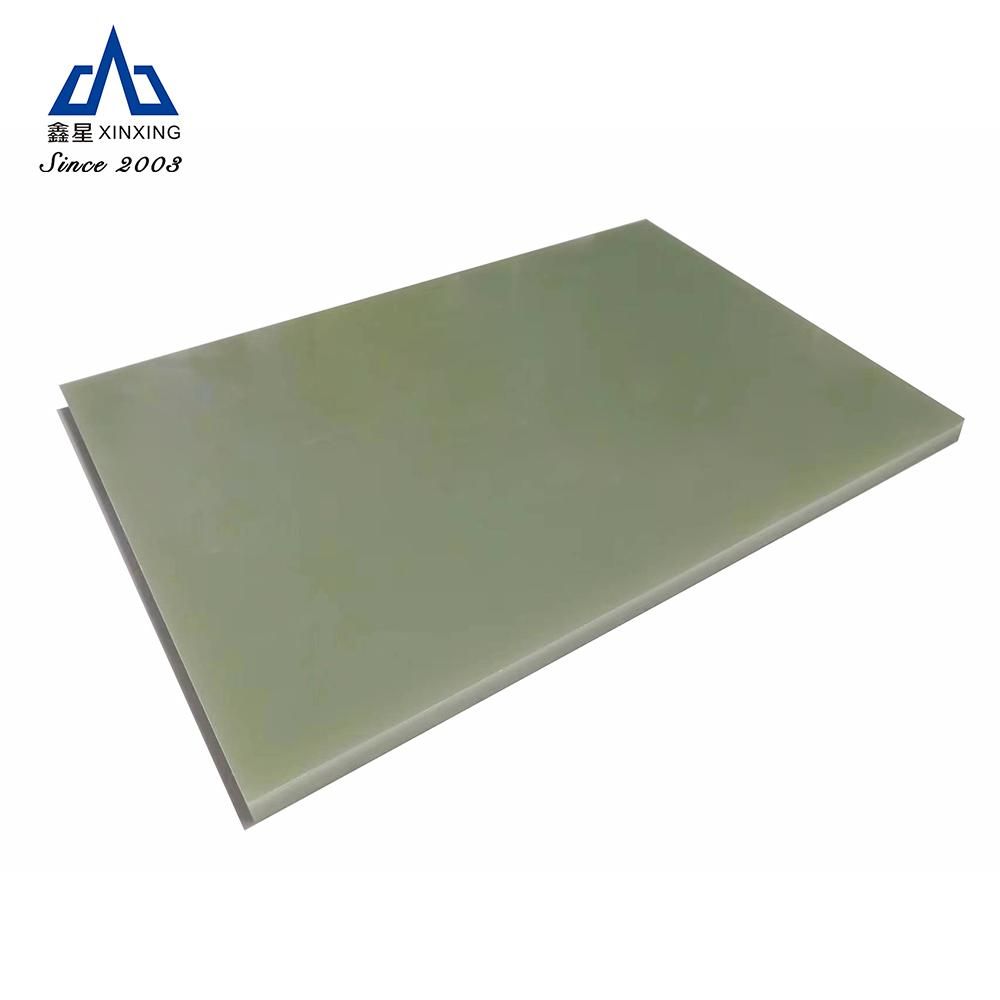

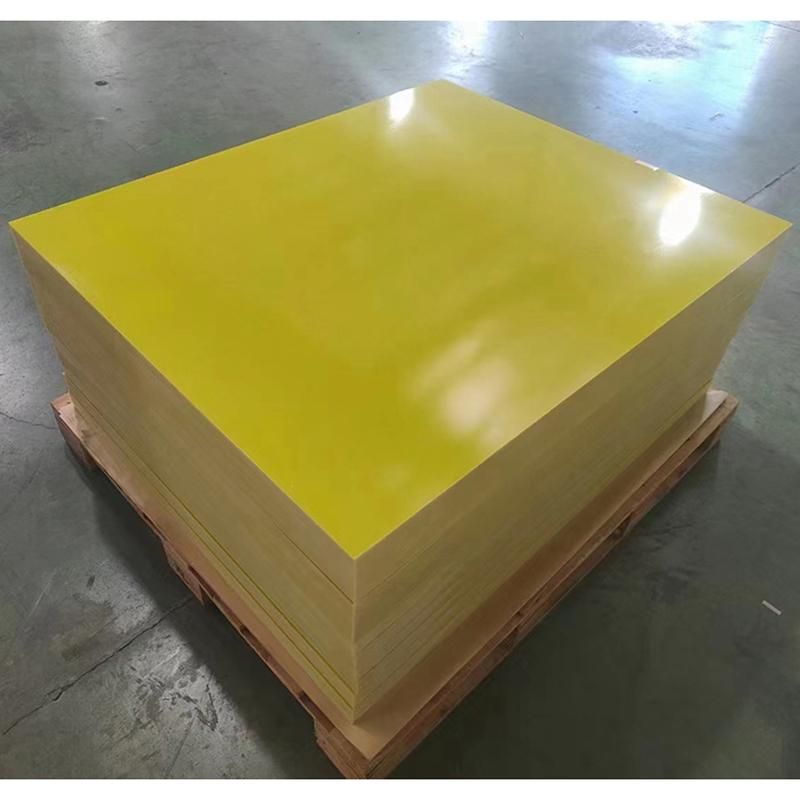

| Xim | Lub teeb GreenYellowBlackTitanium Dawb, thiab lwm yam |

| Thickness | 0.1 hli-200mm |

| Qhov ntev | Qhov loj me yog 1020x1220mm, 1220x2040mm, 1220x2440mm, 1020 * 2020mm; |

| Qhov ntom | 1.8g / cm3 - 2.0g / cm3 |

| Kub Index | 130 ℃ |

| CTI | 600 |

| Cov ntaub ntawv Technical | Nyem qhov no mus download tau |

Cov khoom qhia

NEMA Qib G-10 cov ntaub ntawv yog 7628 fiberglass reinforced laminates, bonded nrog epoxy resin.Nrog siab mechanical thiab dielectric zog, zoo tshav kub thiab yoj tsis kam, kuj nrog zoo machinability; Cov khoom no muaj peev xwm ua tau raws li EU ROHS tus qauv, nws yog dav xa tawm mus rau sab hnub tuaj Aisa, European, Is Nrias teb, thiab lwm yam.

G10 tsis yog lub npe khoom, tab sis qib khoom siv, lub npe G10 los ntawm NEMA grading system qhov twg "G" qauv rau "iav fiber ntau"

Ua raws li cov qauv

TS EN ISO 60893-3-2-2011 Cov khoom siv hluav taws xob thermoset resin muaj zog laminates - Ntu 4: epoxy resin hard laminates, IEC 60893-3-2-2011 insulating cov ntaub ntawv - hluav taws xob thermoset resin industrial hard laminates - Ntu 3-2 ntawm cov khoom siv tshwj xeeb EPGC201.

Daim ntawv thov

Haum rau daim ntawv thov nyob rau hauv kev ua tau zoo hluav taws xob rwb thaiv tsev cov khoom, xws li FPC reinforcement phaj, PCB drilling ncoo, fiberglass meson, iav fiber board potentiometer carbon zaj duab xis luam ntawv, precision ncig saib hnub qub iav sib tsoo (chip), precision kuaj phaj, hluav taws xob (hluav taws xob) khoom rwb thaiv tsev nyob clapboard, insulating phaj, transformer rwb thaiv tsev board, lub cev muaj zog rwb thaiv tsev qhov chaw, sib tsoo log, hluav taws xob hloov hluav taws xob thiab lwm yam.

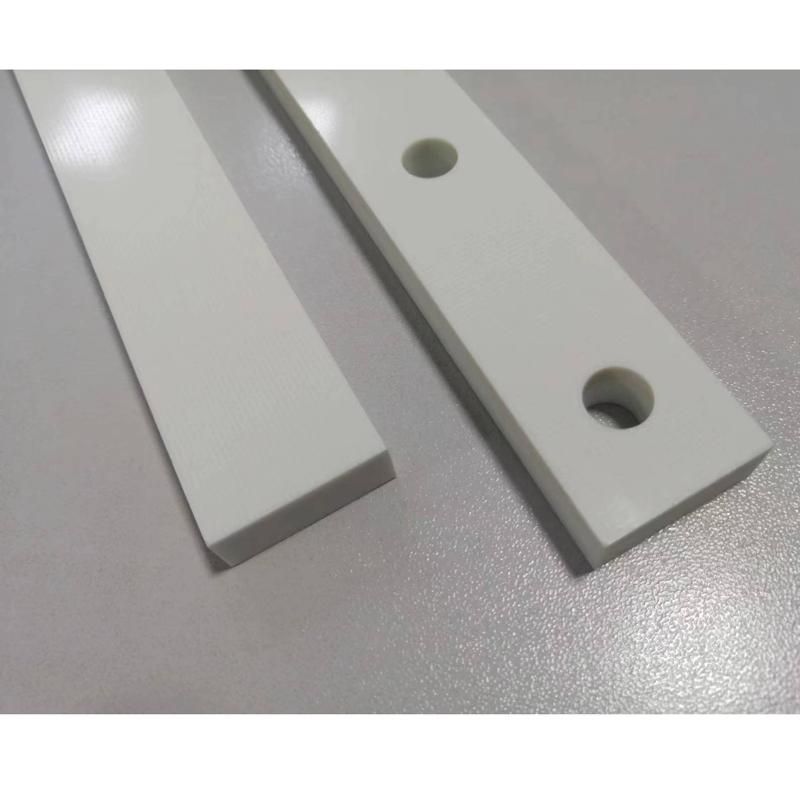

Cov duab khoom

Hnub Kawg Ua Haujlwm (Nyem qhov no txhawm rau rub tawm daim ntawv xeem thib peb)

| Khoom | Chav tsev | Txheem tus nqi | Yam nqi |

| Flexural zog perpendicular rau laminations (MD) | Mpa | ≥340 | 521 ib |

| Charpy cuam tshuam lub zog sib npaug rau laminations (Notched, MD) | KJ/m2 | ≥33 | 63.8 ib |

| Tensile zog (MD) | Mpa | ≥300 | 412 |

| Lub zog hluav taws xob perpendicular rau laminations (1 hli thickness) (ntawm 90 ℃ ± 2 ℃ hauv 25 # transformer roj, 20s kauj ruam los ntawm kauj ruam xeem, Φ25mm / Φ75mm cylindrical electrode) | KV/mm | ≥14.2 | 22.1 |

| Kev puas tsuaj hluav taws xob sib npaug rau cov laminations (ntawm 90 ℃ ± 2 ℃ hauv 25 # transformer roj, 20s kauj ruam los ntawm kev xeem, Φ130mm / Φ130mm phaj electrode) | KV | ≥35 | 88.3 ib |

| Kev txheeb ze Permittivity (1MHz) | _ | ≤5.5 | 4.90 ib |

| Rwb thaiv tsev tsis kam (Taper pin electrodes, thiab qhov sib nrug ntawm electrode yog 25.0mm) | Ω | ≥5.0x1012 | 3.9 x 1014 |

| Rwb thaiv tsev tsis kam (Tom qab 24h immersion hauv dej, siv taper pin electrodes, thiab electrode spacing yog 25.0mm) | Ω | ≥5.0x1010 | 2.3 x 1014 |

| Comparative Tracking Index (CTI) | _ | _ | TSI 600 |

| Qhov ntom | g/cm3 | 1.8-2.0 Nws | 1.97 ib |

Ua raws li cov qauv

TS EN ISO 60893-3-2-2011 Cov khoom siv hluav taws xob thermoset resin muaj zog laminates - Ntu 4: epoxy resin hard laminates, IEC 60893-3-2-2011 insulating cov ntaub ntawv - hluav taws xob thermoset resin industrial hard laminates - Ntu 3-2 ntawm cov khoom siv tshwj xeeb EPGC201.

FAQ

Q1: Koj puas yog tuam txhab lag luam lossis chaw tsim khoom?

Peb yog cov chaw tsim khoom ntawm hluav taws xob insulating composite, Peb tau koom nrog cov chaw tsim khoom thermoset rigid composite txij li xyoo 2003.Our peev yog 6000TONS / xyoo.

Q2: Qauv

Cov qauv yog dawb, koj tsuas yog yuav tsum tau them tus nqi thauj khoom.

Q3: Koj tuaj yeem lav qhov zoo ntawm cov khoom loj li cas?

Rau cov tsos, qhov loj me thiab tuab: peb yuav ua tag nrho kev tshuaj xyuas ua ntej packing.

Rau kev ua tau zoo: Peb siv cov qauv ruaj khov, thiab yuav kuaj xyuas cov qauv tsis tu ncua, peb tuaj yeem muab cov ntaub ntawv tshuaj xyuas cov khoom ua ntej xa khoom.

Q4: Lub sijhawm khoom xa tuaj

Nws nyob ntawm kev txiav txim kom muaj nuj nqis. Feem ntau hais lus, lub sijhawm khoom xa tuaj yuav yog 15-20 hnub.

Q5: Pob

Peb yuav siv cov khoom siv tes ua daim ntawv rau pob ntawm plywood pallet.yog tias koj muaj cov pob tshwj xeeb, peb yuav ntim raws li koj xav tau.

Q6: Them nyiaj

TT, 30% T / T ua ntej, tshuav nyiaj li cas ua ntej xa khoom.Peb kuj lees txais L / C.